Description

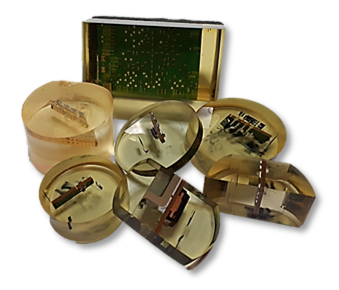

Cross-section preparation is one of the most effective ways in examining how a material is laminated or component is assembled and produced. From cross section, we can determine the different layers’ interaction. And from close observations layer after layer we can easily zoom into the mechanism that caused a failure.

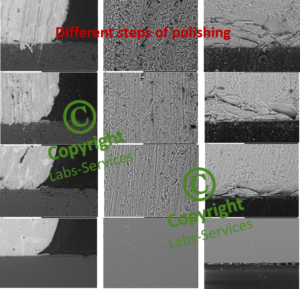

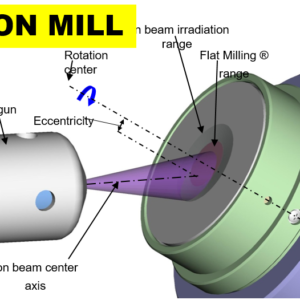

Good cross-section preparation will not disturb, smear or alter the specimen from pointing to the correct conclusion. Therefore the skill and experience of the person preparing the sample is crucial. Our Labs possessed the expertise in Cross-section preparation because we know that samples from customers can be scarce. Some samples photos below to show the steps in polishing.

- Determination of coating thickness or coating continuity.

- Inspection for settling out of filler materials in painted coatings.

- Metallographic sample preparation inspecting for the presence of different metallurgical phases, defects or porosity.

- Measurement of the extent of inter-layer mixing and diffusion in laminated or coated structures.

- Physical failure analysis looking for cracks or evidence of failure initiation sites for mechanisms such as fatigue, corrosion, stress corrosion cracking, poor cleaning practices, buried interfaces, weak boundary layers, etc.

- Component assembly inspection and reverse engineering.